Products Description

Aluminium Oxide Al2O3 Alumina with Low Temperature for Sintering with Injection Moulding Process D99

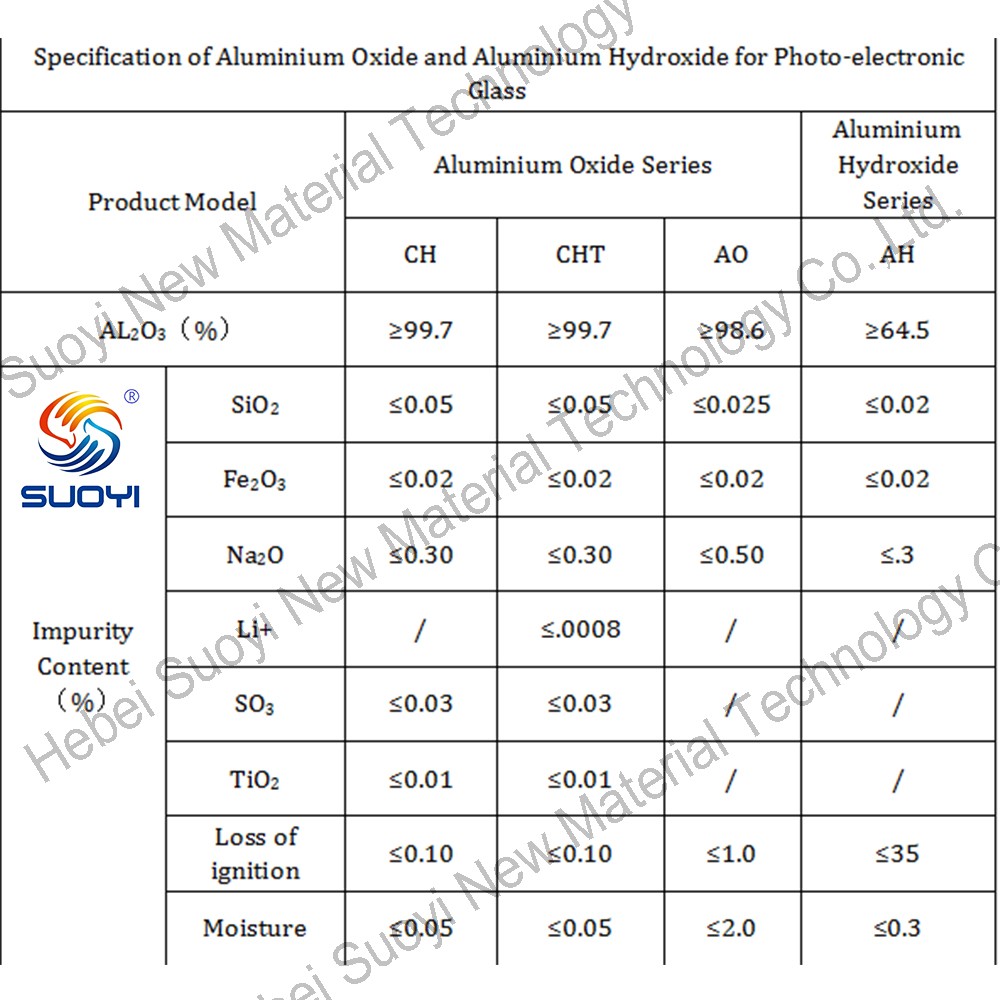

Ceramic Alumina Oxide Al2O3 Powder Oxide Powder for Photoelectric Glass Ceramic

Note: Shrinkage test: cylinder pressure on one side is 80Mpa, body diameter is 30mm, weight is 20g.

1.93% alumina ceramic powder (DC-R93, DC-D93)

This product has special material selection, advanced formula, low temperature, low shrinkage rate, less porosity, high sintering density,

conducive to metallization and other characteristics, ceramic performance is better than 95% ceramics

2.Low temperature 99% alumina ceramic powder (DC-D99)

Using ultrafine powder as raw material, scientifically prepared, can directly spray granulation, porcelain forming temperature is low (1630°

CX2.5h); Small shrinkage (16 +0.5), good tolerance control; High sintering density (3.9g /cm3- 3.92g/cm3), good ceramic properties.

3 . Low temperature 99% alumina ceramic powder for Hot Die Casting (DC-R99)

α-ai2o3 powder with high conversion rate is selected, and the gradation is reasonable. It can be directly used for hot die casting with wax, and

the porcelain temperature is 1650°C. Stable shrinkage, high sintering density (>3.85g/cm3), can be sintered with 95% common alumina porcelain in

the same furnace.

Application

Company Profile

Aluminum Oxide Al2O3 Alumina D99: Superiority in Performance and Versatility

Introduction:

Aluminum oxide, chemically known as Al2O3, is a highly versatile and widely used material in various industries. Alumina D99 is a specific grade of aluminum oxide renowned for its exceptional attributes and superior performance. This product description will delve into the functions, advantages, and applications of Aluminum Oxide Al2O3 Alumina D99, showcasing its immense potential across different sectors.

- Composition and Properties:

Aluminum Oxide Al2O3 Alumina D99 is an advanced ceramic material characterized by its high purity and excellent physical properties. It boasts a chemical composition of at least 99% aluminum oxide, ensuring remarkable reliability and consistency. The product exhibits exceptional hardness, thermal stability, corrosion resistance, and electrical insulation properties, making it an ideal choice for a wide range of applications.

- Exceptional Mechanical Strength:

Alumina D99 possesses outstanding mechanical strength, enabling it to withstand rigorous operating conditions. Its superior hardness contributes to excellent wear resistance, making it highly suitable for demanding environments. With an impressive compressive strength and high fracture toughness, Aluminum Oxide Al2O3 Alumina D99 ensures enhanced durability and prolonged service life.

- Thermal Stability and Heat Resistance:

One of the key advantages of Aluminum Oxide Al2O3 Alumina D99 is its exceptional thermal stability. It exhibits a high melting point and low coefficient of thermal expansion, enabling it to withstand extreme temperature variations without undergoing deformation or structural degradation. This remarkable heat resistance makes it an ideal choice for applications involving high-temperature environments, such as furnace linings, refractory components, and thermal insulators.

- Excellent Electrical Insulation Properties:

Alumina D99 possesses excellent electrical insulation properties, making it an essential material in electrical and electronic applications. It exhibits high dielectric strength, low dielectric loss, and excellent insulation resistance. These characteristics make it a reliable choice for insulating components, circuit boards, high-voltage insulators, and electrical connectors.

- Chemical Inertness and Corrosion Resistance:

Aluminum Oxide Al2O3 Alumina D99 demonstrates remarkable chemical inertness and corrosion resistance. It remains unaffected by most acids, alkalis, and organic solvents, ensuring its stability and integrity even in highly corrosive environments. This property makes it an ideal material for chemical processing equipment, corrosion-resistant coatings, and protective linings.

Applications:

-

Industrial Ceramics: Aluminum Oxide Al2O3 Alumina D99 is widely utilized in the production of advanced industrial ceramics. It serves as a crucial component in manufacturing wear-resistant parts, cutting tools, grinding media, and ceramic bearings. Its high hardness, excellent mechanical strength, and wear resistance make it invaluable in heavy-duty applications where reliability and longevity are paramount.

-

Electronics and Semiconductors: The exceptional electrical insulation properties of Alumina D99 make it indispensable in the electronics and semiconductor industries. It finds applications in the production of insulating substrates, circuit boards, ceramic capacitors, and high-voltage insulators. Its thermal stability and low dielectric loss enable efficient heat dissipation and reliable performance in electronic devices.

-

Refractories and Furnace Linings: Due to its outstanding thermal stability, Aluminum Oxide Al2O3 Alumina D99 is extensively used in refractory applications. It serves as a key component in manufacturing furnace linings, crucibles, kiln furniture, and refractory bricks. Its ability to withstand extreme temperatures and resist thermal shock ensures optimal performance and extended lifespan in high-temperature environments.

-

Chemical Processing: Alumina D99’s chemical inertness and corrosion resistance make it a preferred material for chemical processing equipment. It finds use in the production of reaction vessels, pumps, valves, and pipes. Its ability to withstand corrosive chemicals ensures safety, reliability, and long-term operational efficiency in chemical plants and laboratories.

-

Environmental Protection: Aluminum Oxide Al2O3 Alumina D99 plays a vital role in environmental protection applications. It is commonly used in catalytic converters, air filters, and pollution control systems. Its high surface area and catalytic properties enable efficient removal of harmful pollutants, contributing to cleaner air and a healthier environment.

Conclusion:

Aluminum Oxide Al2O3 Alumina D99 stands as a versatile and high-performance material, widely appreciated for its exceptional attributes and myriad applications. Its remarkable mechanical strength, thermal stability, electrical insulation properties, and corrosion resistance make it indispensable across various industries. From industrial ceramics and electronics to refractories and chemical processing, this advanced ceramic material continues to revolutionize diverse sectors. With its outstanding properties and enduring reliability, Aluminum Oxide Al2O3 Alumina D99 offers unparalleled value and immense potential for a wide range of industrial applications.